- Driven by China's economy, German industry is optimistic about its development prospects in 2021

- Application of photoelectric switch in intelligent lock

- Application of proximity switch in action control and limit protection of CNC cutting machine

- Dealing with inverter failure: replacement or upgrade?

- Application of photoelectric detection and laser strike technology in UAV counter system

- Application of infrared sensor technology in the screening of pneumonia temperature

- Design and application of intelligent dispatch unattended system in coal mine

- Industrial Internet of things enters the era of artificial intelligence

Intelligence is the most important trend of manufacturing industry in recent years. After market education in the past few years, the degree of market inquiry has begun to improve in the past two years. Since 2016, the IT industry has set off an upsurge of artificial intelligence (AI). The integration of AI and Internet of things will become the main system in various vertical fields in the future. In the manufacturing industry, AI will also become one of the core computing architectures of industrial Internet of things.

Since Germany took the lead in calling out industry 4.0, relevant technologies have also made rapid progress, including industrial Internet of things, big data analysis, robotics and other technologies. So far, it has gradually created a new type of intelligent factory and a new industrial standard.

Especially in recent years, the wave of artificial intelligence (AI) has given industry 4.0 a new development direction. It is clear that the differences between automation and intelligent mobility, including machine vision, deep learning and other artificial intelligence technologies based on algorithm analysis, have become a new trend in the future development of industry 4.0, which not only makes the technology of automation and robot more accurate, but also makes the manufacturing industry more competitive Enter into such as no artificial factory and other new areas of science and technology.

At present, there are three major trends in intelligent manufacturing. The first is production network, which mainly applies manufacturing operations management, The second trend is the perfect integration of virtual simulation and real physical system. Every step in the manufacturing process will be designed, simulated and optimized in the virtual world for real physical system The world includes materials, products and factories. A highly simulated digital twin (twin model) has been established. The third trend is cyber physical In this system, the product information will be input to the product components themselves, they will directly communicate with the production system and equipment according to their own production needs, issue the next production process instructions, and command the equipment to organize their own production. This independent production mode can meet the customized needs of each user.

Building operation mode with big data

The above three trends will be integrated with AI to a certain extent in the future. For example, AI computing function will be designed in production line monitoring, robots, and unmanned vans. The main reason is the trend of mass customization, and the difficulty of various production situations such as product types and production line transfer that factories need to face will also increase greatly. Although through the analysis of sensors and big data, managers can understand In order to master more and more information to help decision-making, but also because the amount of information is increasing, increasing the pressure of information analysis for managers, and the market is changing more and more quickly, the speed of human analysis may have become more and more difficult to keep up with, providing faster and faster front-end data, naturally it is more difficult for the machines on the manufacturing site to quickly respond to customer needs. AI is applied to the manufacturing industry, It will enable the system to find out the regular establishment mode from the big data analysis, and then learn to avoid the previous mistakes, and even make the prediction in advance. When it is applied to the manufacturing field, it can not only shorten the downtime, but also timely adjust the production line, and reduce the frequency of dead materials and wastes.

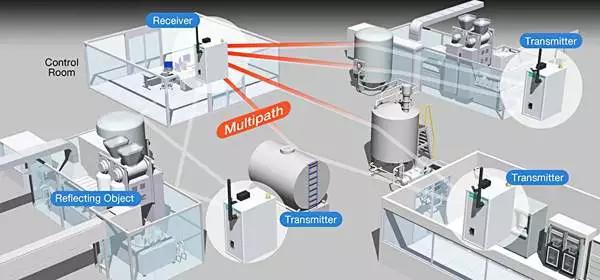

For the industrial Internet of things, obtaining and analyzing data is the core task, and the data points from sensors can be transformed into operational insights through multiple stages. The industrial Internet of things platform includes scalable data processing process, which can process real-time data that need immediate attention, and meaningful data only for a period of time. When the pressure and temperature thresholds are detected, the industrial Internet of things platform can not be changed After the abnormal combination, it may be too late for the IOT platform to shut down the LPG filling machine. It should detect the abnormality within milliseconds, and then trigger an immediate response according to the rules.

In terms of current development, AI has several algorithms. For example, the core of hot path analysis is the rule engine responsible for detecting anomalies. The Internet of things platform embeds complex rule engine, which can dynamically evaluate complex patterns from sensor data flow. Domain experts who understand patterns and data formats define the benchmark threshold and routing logic of the rule engine, which acts as the rule engine Rule engine has become the core of the Internet of things platform. One of the key areas of machine learning is to find patterns from existing data sets, group similar data points, and predict the value of future data points.

High order algorithms related to machine learning can be used for classification and prediction analysis. Because these algorithms can learn from existing data, and most of the IOT data are based on time series, these algorithms can predict the future value of sensors according to historical data. The combination of these multiple machine learning algorithms will replace the traditional rule engine in the industrial IOT platform However, domain experts still need to act according to the definition of conditions, but these intelligent algorithms provide higher accuracy and accuracy.

AI + hi greatly improves efficiency

One of the biggest applications of machine learning in the industrial Internet of things is predictive maintenance of equipment. Through correlation and analysis of mode changes, equipment failure can be predicted, and key indicators such as the remaining service life of equipment can be reported. Predictive maintenance can also be applied in aerospace, manufacturing, automobile, transportation, logistics and supply chain, for example, the predictive model is arranged in the automobile service center In the aviation industry, the goal of predictive maintenance scheme is to predict the possibility of flight delay or cancellation based on maintenance history and flight route information.

Observing the development trend of the Internet of things, at present, the industrial Internet of things is one of the fastest growing categories of all vertical applications. AI in the industrial Internet of things is mainly to assist operators and managers, screen data extracted from a large number of devices, and make judgments. However, the current AI can not make logical decisions. Therefore, in the field of manufacturing, AI must be combined with human intelligence to make decisions It will be the best benefit of the system.

- Driven by China's economy, German industry is optimistic about its development prospects in 2021

- Application of photoelectric switch in intelligent lock

- Application of proximity switch in action control and limit protection of CNC cutting machine

- Dealing with inverter failure: replacement or upgrade?

- Application of photoelectric detection and laser strike technology in UAV counter system

- Application of infrared sensor technology in the screening of pneumonia temperature

- Home - About us - New products - News - Download - FAQ - Feedback - Contact us - Sitemap

- Powered by semcms 4.6 Copyright @ 2009 - 2025 omelok

13670175782

13670175782

2021/4/15

2021/4/15